Disease control programme for wine grapes

UK Grapevine disease management overview

Disease management is a persistent issue in wine grape growing. The three most economically damaging diseases are powdery mildew, downy mildew and botrytis. At present, disease control is reliant on conventional chemical fungicides, however, these programmes are expensive, ecologically damaging and are experiencing an increase in resistance to key active ingredients.

Biopesticide use is yet to be widely adopted in the sector – but by using them we’ve delivered a high level of broad-spectrum control, whilst also being environmentally sustainable, low-cost and free of the risk of resistance. Commercially too, the use of biopesticides is aligned with the demands of consumers, who appreciate wines produced to a high environmental standard.

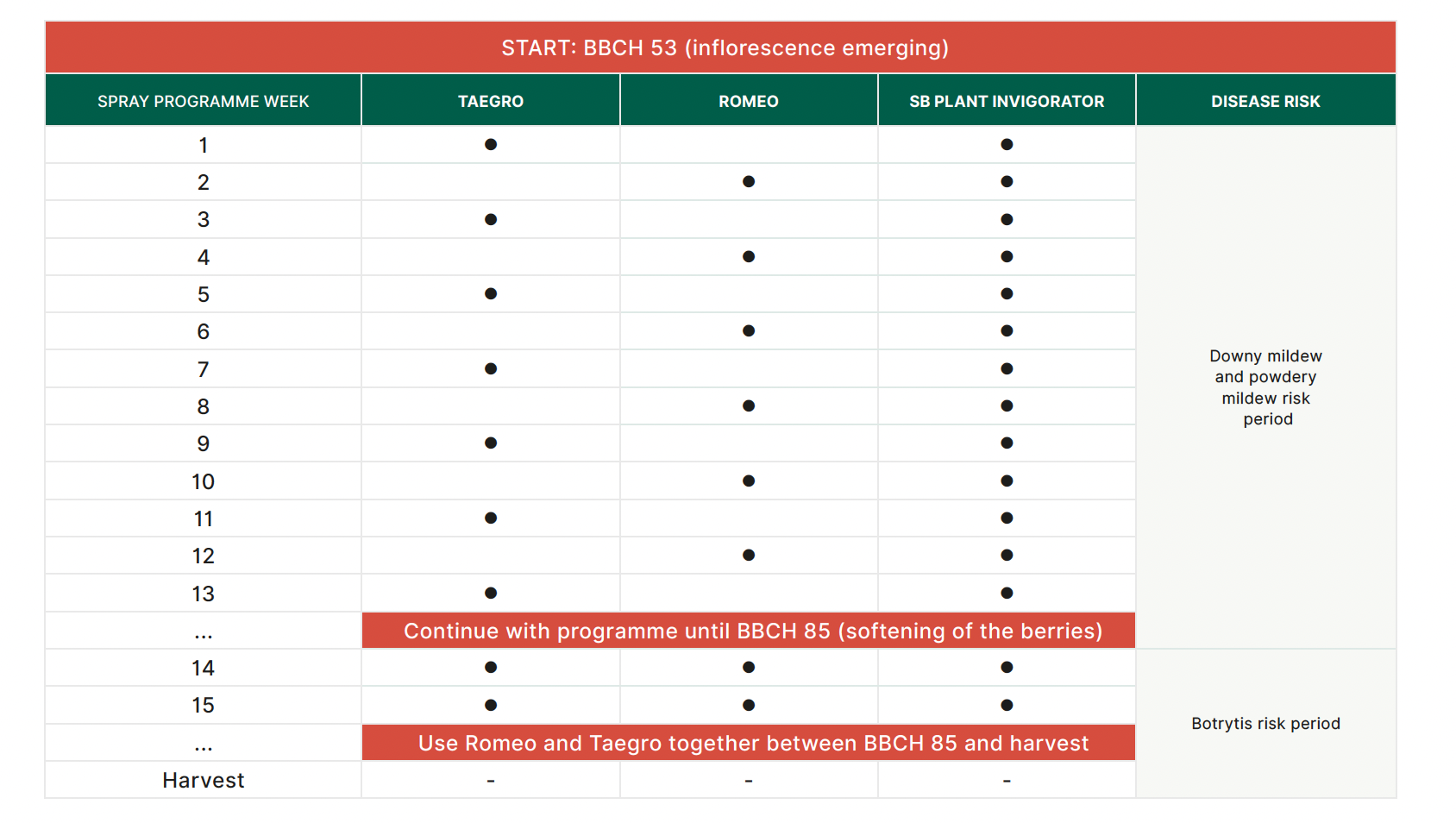

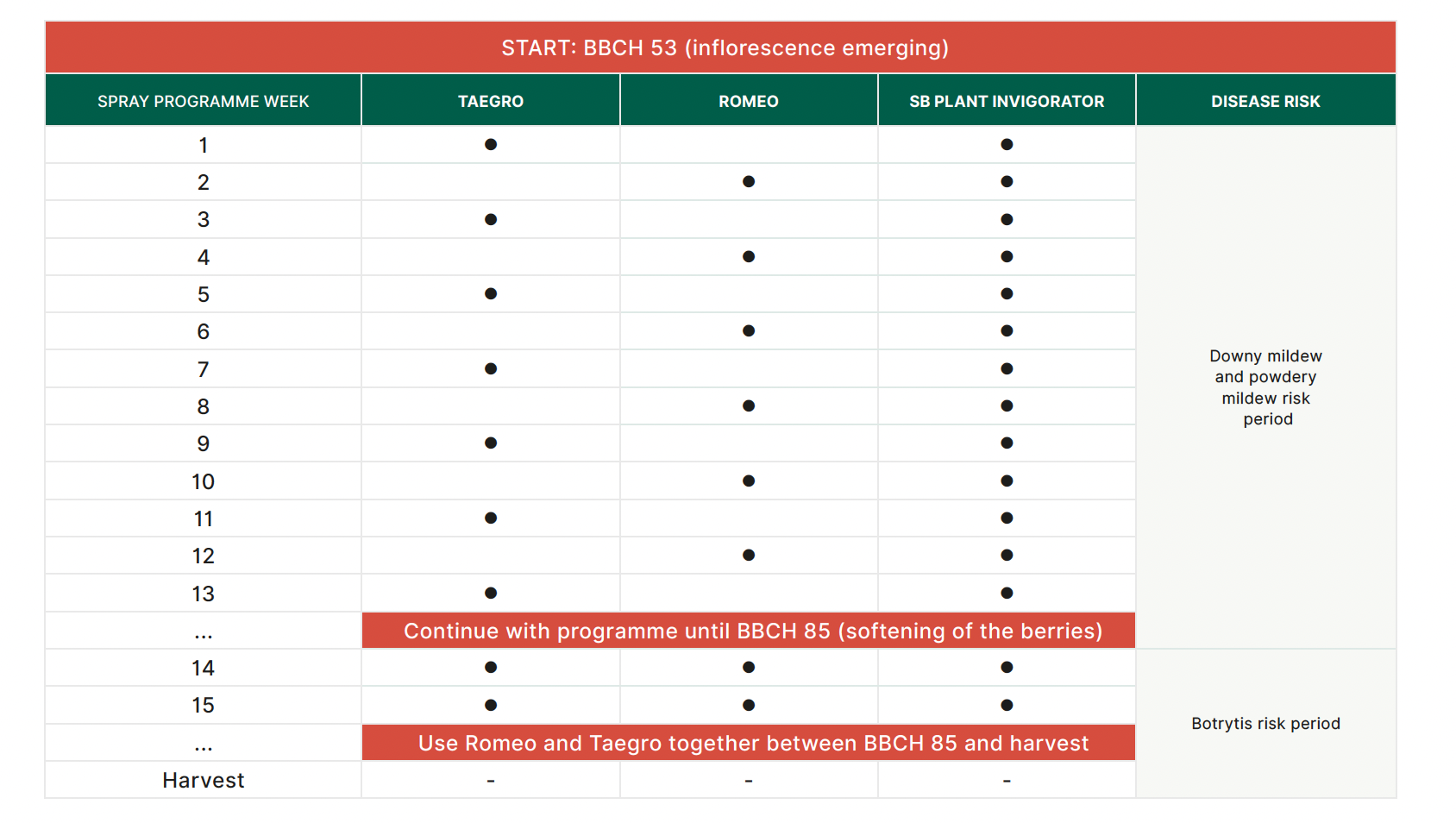

Fargro’s ecological spray programme outline

Our programme combines three biopesticides (Taegro, Romeo, SB Plant Invigorator).

Modes of Action:

•Taegro, Bacillus amyloliquefaciens strain FZB24 - Bacteria colonises the plant surface and secretes anti-fungal compounds to inhibit establishment of spores

• Romeo, Cerevisane (denatured brewers yeast) - Denatured yeast cells are recognised as fungus by the plant and elicit natural plant anti-pathogen defences

• SB Plant Invigorator, Mix of ecologically friendly and phyto-safe surfactants - Degrades fungal hyphae and spores

How does it work?

Starting at BBCH 53 (inflorescence emerging), Taegro is used first to establish a protective population of bacteria on the plant surfaces. This is then alternated weekly with Romeo to prolong the efficacy until the next Taegro application. SB Plant Invigorator is used throughout the spray programme, both for its physical mode of action against powdery mildew, to facilitate physical compatibility, and to help with Taegro establishment on the leaf.

Once BBCH 85 (softening of the berries) is reached, Taegro and Romeo are applied together to give strong protection of the grapes as harvest approaches. This is due to increased risk of botrytis when sugar levels are high.

Benefits of programme

• Lower cost than conventional programmes

• Application is easy and practical

• No chemical residues on product

• No damage to environment and beneficial soil life

• No exposure of staff to chemical pesticides

• Biopesticides that work with natural plant defences increase levels of desired polyphenols

Product overview

|

PRODUCT |

ACTIVE INGREDIENT |

MAX. NO.APPLICATIONS |

RATE |

HARVEST INTERVAL |

|

Taegro |

Bacillus amyloliquefaciens strain FZB24 |

10 |

0.37kg/ha |

1 day |

|

Romeo |

Cerevisane (denatured brewers yeast) |

10 |

0.25kg/ha |

1 day |

|

SB Plant Invigorator |

Mix of ecologically friendly and phyto-safe surfactants |

N/A |

1ml/l |

N/A |

Template Spray Schedule

Notes:

• Apply in tank mix and always add SB Plant Invigorator first

• For best results apply in late afternoon/evening

• Amount of applications is liable to change depending on development of crop

• Programme can be extended should harvest dates change – please be conscious of harvest intervals and application limits on production labels

The programme in practice

We trialled the below spray programme at Gusbourne Estate's Sussex site, located at Selhurst Park, Halnaker, Chichester,

PO18 0LZ

• Application area: 0.3ha split evenly across two adjacent fields, 75m elevation, west facing

• Crop: Grapevine, variety: Chardonnay

• Target Application type: Boom spray (tractor mounted)

• Spray start date: Week commencing 26.06.2023

• Harvest: Week commencing 02.10.23

• Water Rate: 500L/ha

Notes:

• Apply in tank mix and always add SB Plant Invigorator first

• For best results apply in late afternoon/ evening

• Programme can be extended should harvest dates change – please be conscious of harvest intervals and application limits on production labels

• A biostimulant containing Ascophyllum nodosum and amino acids was also applied with each weekly application

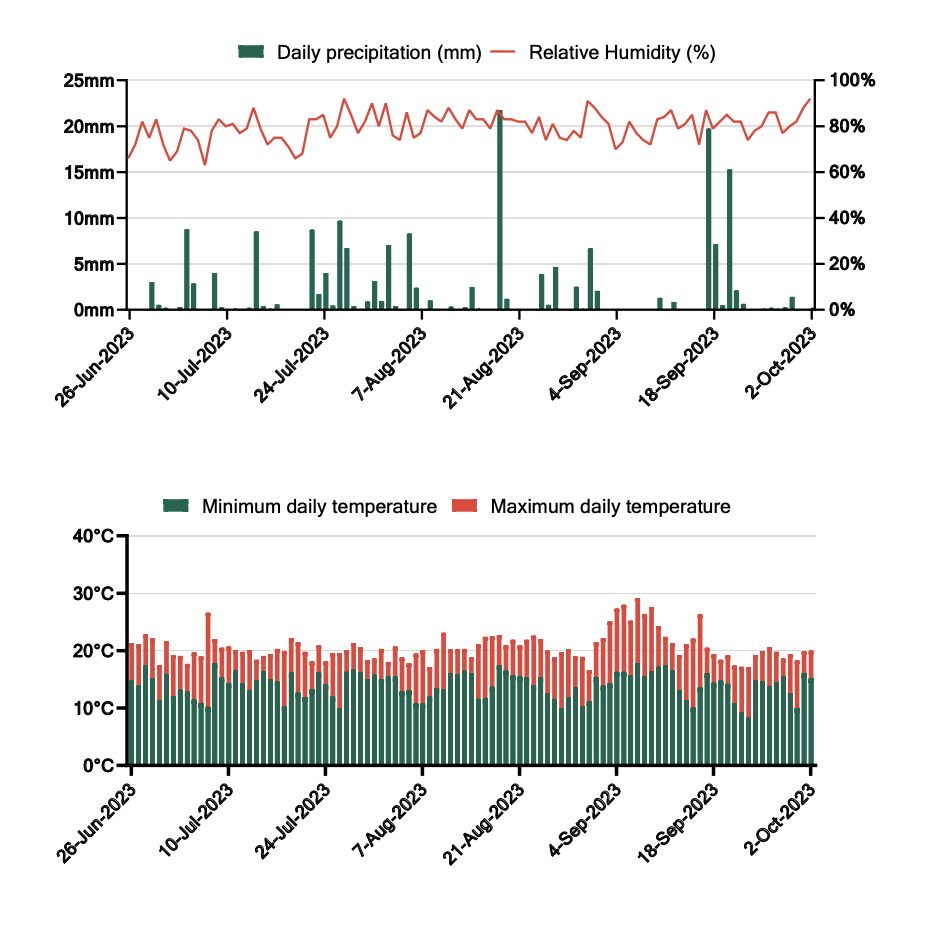

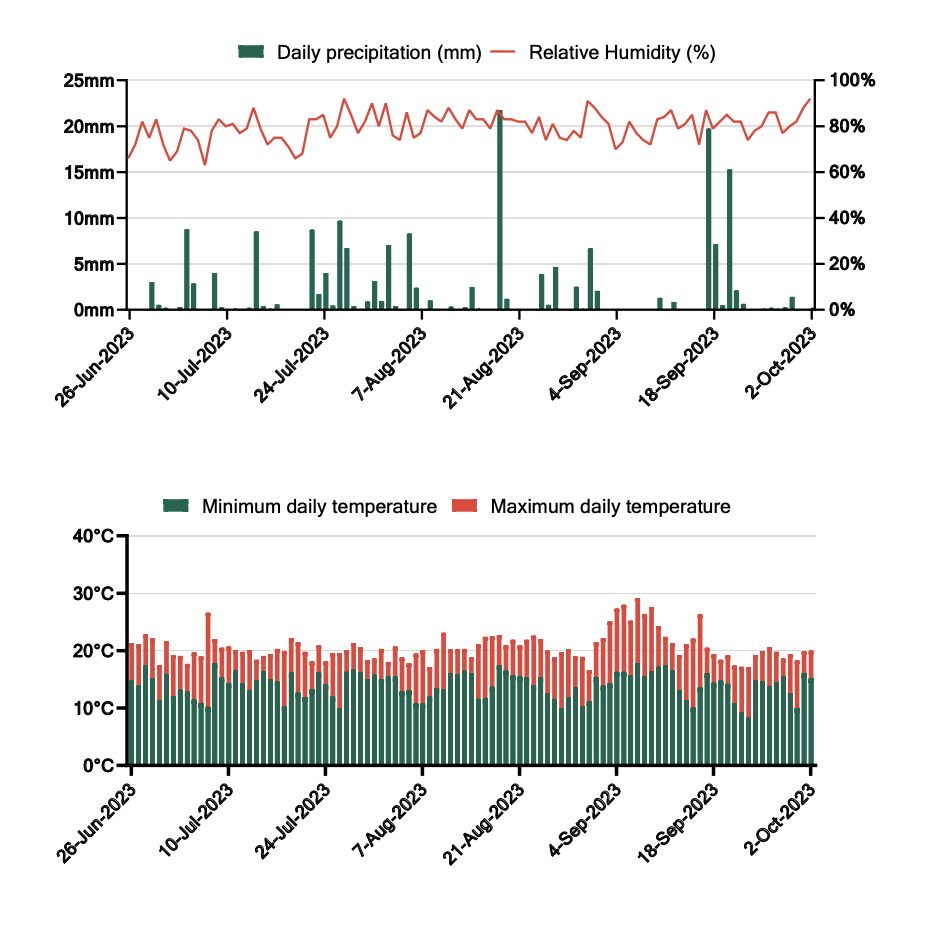

Disease pressure

The growing season started with high spring temperatures, but this gave way to an exceptionally mild and wet July and August before a hot and dry September and start of October.

Powdery mildew pressure: Medium

The hot, humid, but dry start and end to the season encouraged powdery mildew but the heavy rainfall in July and August restricted its propagation in the middle months. The site has a history of susceptibility to the disease.

Downy mildew pressure: High

The very wet conditions and mild temperatures in July and August provided optimal conditions for the propagation and infection of the vines with downy mildew.

Botrytis pressure: Low

The warm temperatures and dryness during veraison and harvest suppressed the infection and spread of Botrytis.

Results

"The spray programme was easy to apply and achieved a high level of control of powdery mildew, downy mildew and botrytis. We lost significantly less than 1% of bunches to disease." - ADAM FODEN GROWER, GUSBOURNE

Exceptionally high levels of control were achieved for all three diseases. The programme performed equally as well as the conventional chemical programme in adjacent rows and blocks.

CONTROL LEVEL 99.6% of bunches harvested (0.4% loss to pests, disease and cultural issues combined)

Costings

|

RODUCT |

RATES |

COSTINGS |

|

Taegro |

8 applications at 0.37kg/ha |

£755/ha ex VAT |

|

Romeo |

7 applications at 0.25kg/ha |

£123/ha ex VAT |

|

SB Plant Invigorator |

14 applications at 0.5L/ha |

£218/ha ex VAT

|

|

Costs based on 2023 RRP prices |

Total £1,095/ha ex VAT |

• Image one:

End of July - clean foliage observed with little sign of powdery or downy mildew, despite pressure from conditions.

• Image two:

End of August - disease free developing bunches.

• Image three:

End of September - clean bunches ready for harvest.

Taegro MAPP Number 19204 Romeo MAPP Number 19170. Use plant protection products safely. Always read the label and product information before use. Further detail on warning symbols and phrases is included on the labels and leaflets.

Download the complete case study using the download link below.

Find out more

Natural Disease Management Programme for Viticulture

This programme utilises biopesticides and foliar nutrition to create a strong and resilient crop – enabling it to withstand downy mildew, powdery mildew and botrytis without the requirement of chemical pesticides.

Chemical Pesticide Free ✔

Low Cost ✔

Easy to apply ✔

Programme cost = £1,999/ha*

*If ordering for a minimum of 5ha

This programme will qualify you for SFI funding as it has been designed by BASIS certified agronomists.

The programme utilises different regimes at each development stage. The sprays in Table 1 are estimates for 2025 – the developmental stages may be longer or shorter than estimated and so you must tailor your applications accordingly based on the programme by stage in table 2. If you require advice on applications please contact technical@fargro.co.uk

Table 1 - Forecasted applications for 2025

Notes:

- Apply products in tank mix.

- For best results apply in late afternoon/evening.

- Amount of applications is liable to change depending on development of crop.

- Programme can be extended should harvest dates change – but please be conscious of harvest Intervals and application limits on production labels.

Table 2 - Programme Breakdown by development stage

Table 3 - Volumes required for 5 hectares

Notes:

• Apply in tank mix and always add SB Plant Invigorator first

• For best results apply in late afternoon/ evening

• Programme can be extended should harvest dates change – please be conscious of harvest intervals and application limits on production labels

• A biostimulant containing Ascophyllum nodosum and amino acids was also applied with each weekly application

Disease pressure

The growing season started with high spring temperatures, but this gave way to an exceptionally mild and wet July and August before a hot and dry September and start of October.

Powdery mildew pressure: Medium

The hot, humid, but dry start and end to the season encouraged powdery mildew but the heavy rainfall in July and August restricted its propagation in the middle months. The site has a history of susceptibility to the disease.

Downy mildew pressure: High

The very wet conditions and mild temperatures in July and August provided optimal conditions for the propagation and infection of the vines with downy mildew.

Botrytis pressure: Low

The warm temperatures and dryness during veraison and harvest suppressed the infection and spread of Botrytis.

Results

"The spray programme was easy to apply and achieved a high level of control of powdery mildew, downy mildew and botrytis. We lost significantly less than 1% of bunches to disease." - ADAM FODEN GROWER, GUSBOURNE

Exceptionally high levels of control were achieved for all three diseases. The programme performed equally as well as the conventional chemical programme in adjacent rows and blocks.

CONTROL LEVEL 99.6% of bunches harvested (0.4% loss to pests, disease and cultural issues combined)

Costings

|

RODUCT |

RATES |

COSTINGS |

|

Taegro |

8 applications at 0.37kg/ha |

£755/ha ex VAT |

|

Romeo |

7 applications at 0.25kg/ha |

£123/ha ex VAT |

|

SB Plant Invigorator |

14 applications at 0.5L/ha |

£218/ha ex VAT

|

|

Costs based on 2023 RRP prices |

Total £1,095/ha ex VAT |

• Image one:

End of July - clean foliage observed with little sign of powdery or downy mildew, despite pressure from conditions.

• Image two:

End of August - disease free developing bunches.

• Image three:

End of September - clean bunches ready for harvest.

Taegro MAPP Number 19204 Romeo MAPP Number 19170. Use plant protection products safely. Always read the label and product information before use. Further detail on warning symbols and phrases is included on the labels and leaflets.

Download the complete case study using the download link below.